ZGF/GSF Type HCL Gas and HCL Acid synthesis Furnace

The company is a comprehensive company integrating design, manufacturing, anti-corrosion construction and system (engineering) design. It can provide anti-corrosion technology and products for many fields that need anti-corrosion applications.

Key words:

graphite heat exchanger | graphite falling film absorber | hydrogen chloride and hydrochloric acid synthesis furnace

Classification:

Description

1.

Synthesis of hydrogen chloride and by burning hydrogen and chlorine together in graphite synthesis furnace has proved to an economical and reliable operation. Synthesis Unit supplied by XInbao demonstrate their capability in operation through their unquestioned advantages:

*Production of hydrochloric acid in a concentration of 1 to 38% HCL from chlorine and hydrogen, using water or hydrochloric acid as the absorbing liquid. *Dry HCL gas of up to 97% purity at 2.0 barg are also can be produced in the synthesis unit. Anhydrous HCL gas of 99.9% purity and up to 6barg can be manufactured in our desorption units made of graphite. *As an HCL recovery measure, HCL gas from other plants can be fed into the synthesis unit and absorbed together with manufactured gas to produce hydrochloric acid. *Chlorine residual gas or sniff gas from other processes can be combusted together with the concentrated Cl2 gas and H2 gas to produce HCL. *Weak acid or azeotropic hydrochloric acid can be fed into the absorber as absorbing liquids and brought up to the required acid concentration. *Cl2 gas with a higher O2 content can be combusted in hydrogen chloride synthesis unit without greatly affecting the service life of the burner or the combustion chamber. For safety reason the O2 content in the H2 must be below 4%. *Heat recovery: The combustion heat of H2 and CL2 in the HCL synthesis unit can be put to effective use. The energy can be recovered in the form of steam or hot water by suitable adaption of the combustion chamber.

2. Technical characteristics

Material system

Operating pressure: 60-80kpa;

Design pressure: 0.1MPa

Gas outlet temperature:<160 ℃

Cooling system

Operating pressure: atmospheric pressure

Design pressure: 0.4Mpa

Cooling water outlet temperature:<40 ℃

HCL (converted to 100%) production: 10000 to 30000 tons/year

3. Structural type, specifications and dimensions

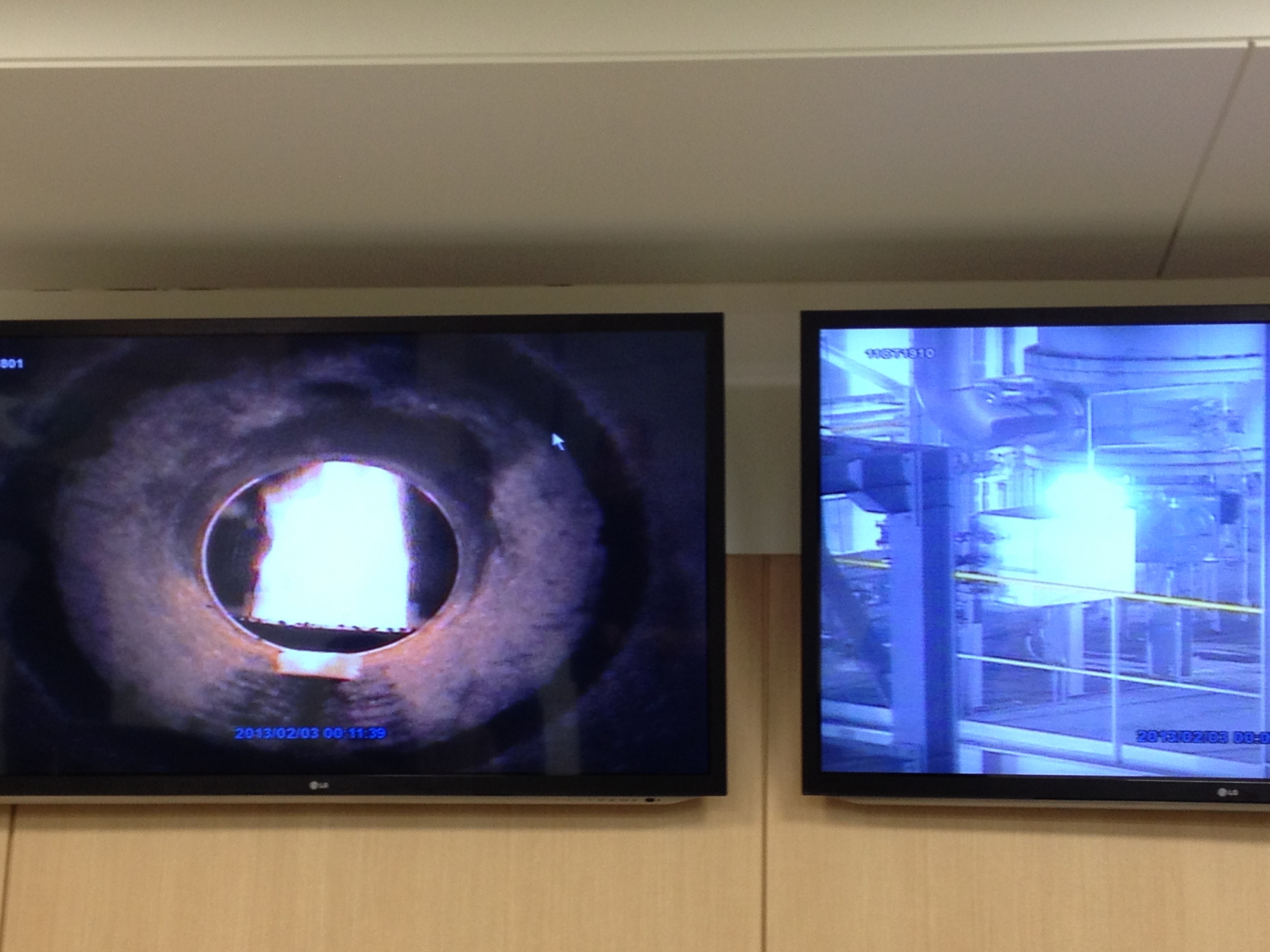

1) The structural type is shown in the attached figure

4. Main advantages

Compared with traditional two in one and three in one graphite synthesis furnaces, the positive pressure two in one graphite synthesis furnace has its unique advantages:

1) High production capacity and operational flexibility

2) Direct supply of high-quality hydrogen chloride

3) Good acid production quality

4) Strong security

5) Investment Province

6) Long lifespan

We use stable quality of chemical special graphite and fine particle graphite as raw materials, the use of advanced technology synthesis of resin as impregnating agent, through a complete process, expand the scope of application of impregnated graphite, to provide you with a variety of highly corrosive media products.

We wholeheartedly provide you with systematic design and manufacturing, especially in HCL, hydrochloric acid synthesis system, concentrated acid desorption system, dilute acid total desorption system, secondary brine refining system, organic matter purification system, adiabatic absorption and other systems, which can meet the needs of anti-corrosion and high-quality products in the production process. At the same time, our technology and products are also widely used in chemical, petroleum, medicine, metallurgy, electronics, food and other fields.

Related Products

Welcome your message consultation

If you are interested in our products, please leave your contact information, we will contact you as soon as possible, thank you!